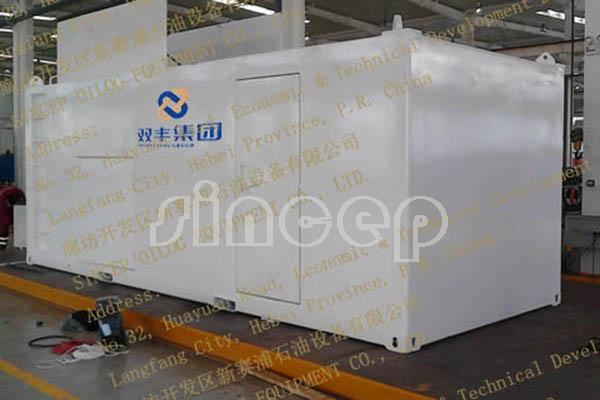

The LHM3470Q coaxial double-drum electric-driven logging skid-mounted winch is a split skid, including a winch skid and a power skid. The winch skid is a two-cabin, fully enclosed structure, which is an operating cabin and a winch cabin. The skid body is container-shaped, and the skin and frame are made of low-temperature resistant steel with good sealing and thermal insulation performance. An insulating canvas cover is installed on the outside, which can be transported at a low temperature of -60℃, and the entire skid can work normally at -40℃. The top of the skid body and the winch assembly are equipped with lifting points and four-limb crimping lifting rigging. The bottom of the skid body is equipped with container corner fittings for easy transportation. The layout inside the skid is compact, which conforms to the characteristics of marine and land platform operations. The skid floor is made of patterned aluminum plate, which is beautiful and durable.

The power source of the skid-mounted winch is a power skid or an external well site power supply. The winch system fully considers the low-temperature environment, and the materials and greases that are resistant to low temperatures are selected. In addition, there are motors and their control systems, cooling systems, reducers and transmission systems, mechanical rope arrangement devices, measurement systems, lighting and other accessories in the cabin.

The six walls of the operation cabin are thickened with flame-retardant polyurethane foam, and the inner skin is brushed stainless steel plate. The cabin is decorated with stainless steel. The cabin is thermally insulated and beautiful, with good corrosion resistance, suitable for offshore platform operations. The cabin is equipped with frequency conversion cabinets, operating tables, distribution boxes, electric heaters, workbenches, data cabinets, operating seats, tool boxes, lighting, etc., and centralized control of winch operations is carried out in the cabin.

Main technical parameters of LHM3470Q electric drive skid-mounted winch:

I. Power system

1. Diesel generator set

2. Model: 6BTAA5.9-G2

3. Rated power: 110/120KW

4. Power factor: 0.8

5. Output voltage: 400/230V

6. Maximum (standby) output current: 216.5A

7. Rated speed: 1500 r/min

8. Fuel: No. 0 clean diesel in summer; choose appropriate light diesel according to local environment in winter

II. Skid assembly parameters

1. Seamless steel pipe welded frame, outer skin is 3mm steel plate, inner skin of operating cabin covered with plastic plate

2. Flame-retardant polyurethane foam treatment on six sides of operating cabin

3. Overall dimensions of the whole skid (length * width * height): 6058×2438×2438mm

4. 2 electric heaters, 1 electric oil heater. 5. Curb weight: about 15050 kg

III. Electric drive system

1. Frequency converter

1.1 Frequency converter model: ABB ACS800

1.2 Principle and composition: ACS800 is a transmission module for controlling AC motors and can work in four-quadrant mode. Including the incoming line rectifier and the motor side inverter.

2. Main motor

2.1 Main motor model: ATD-CJ200D

2.2 Main parameters of the main motor: rated power 70KW; rated speed 3300rpm; rated torque 202N.m; cooling method: water cooling.

2.3 Control method: The main motor is frequency conversion control.

3. Backup motor

3.1 Backup motor model: SEW DR132M

3.2 Only used in emergency situations, pay attention to speed control, and cannot be used for operation.

IV. Winch assembly

1. Coaxial double drum

2. Drum capacity: 7000m each (Ф11.8mm, Ф2.4mm)

3. Maximum lifting capacity: 65kN

4. Cable speed: 30~7000m/h

5. Reducer model: RR180DMS/21.5

6. Brake type: 1) Belt type, mechanical hand brake 2) Motor neutral brake

V. Power supply system

1. External power supply AC380V/50Hz; AC220V/50HZ

2. Generator set Model: DCS120 Power: 110/120KW Voltage: 380V/50Hz